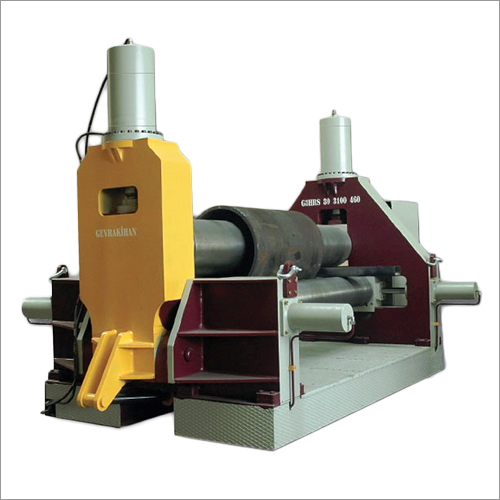

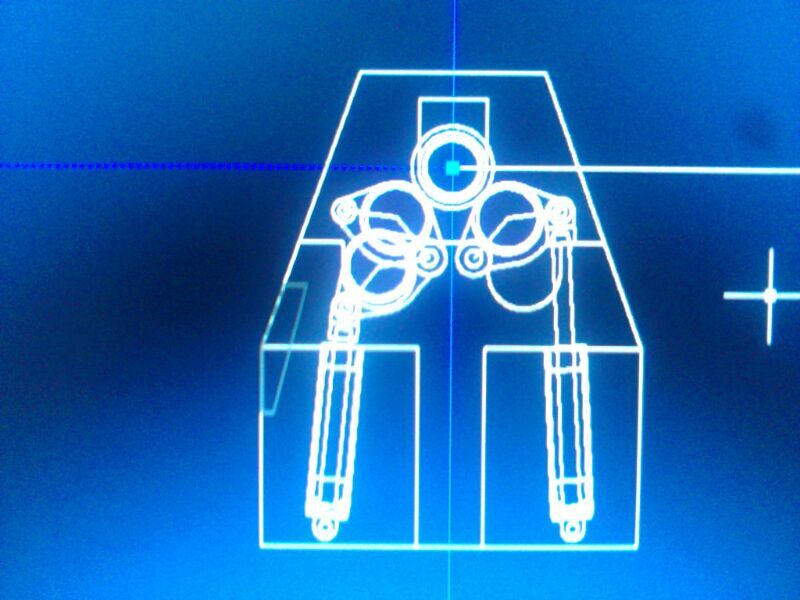

Hydraulic Plate rolling Machine

Price 2500000.0 INR/ Unit

Hydraulic Plate rolling Machine Specification

- Motor Speed

- 1500 RPM

- Automation

- Semi Automatic

- Raw Material

- Mild Steel

- Power

- 25 Ampere (amp)

- Place of Origin

- India

- Output

- 100 Tons Per Month

- Bend Radius

- 50 Centimeter (cm)

- Product Type

- PLATE ROLLING BENDING MACHINES

- Machine Type

- HYDRAULIC

- Weight

- 20000 Kilograms (kg)

- Color

- As Per Client's Requirement.

- Usage

- Plate Bending And Rolling

- Bending Strength

- 100 Ton

- Bending Speed

- 4 Meter Per Minute

- Bending Angle

- 180

- Voltage

- 25 Ampere (amp)

Hydraulic Plate rolling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- INDIA

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 4 Week

- Sample Available

- No

- Packaging Details

- Standard Packing Or As Per CLient's Requirement,

- Main Export Market(s)

- Australia, Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Hydraulic Plate rolling Machine

Industrial Plate Bending Machine is utilized for bending purposes in the industries and is suitable in the reasonable manner. It is designed and manufactured using optimum grade material and emerging techniques under the visionary supervision of trained professionals. It is well-known for its excellent operational fluency, easy usage longer life and generates less noise. We provide this Industrial Plate Bending Machine to our clients in different specifications as per the information laid down by our customers.

Precision and Power in Plate Bending

Our Hydraulic Plate Rolling Machine delivers a reliable 100-ton bending strength, accommodating various mild steel plate thicknesses. Its 180-degree bending angle and 50 cm bend radius are engineered to handle demanding industrial applications, ensuring accuracy in every roll without compromising speed or safety.

Optimized for High Output and Efficiency

Designed for continuous industrial usage, this machine processes up to 100 tons of output per month at a rapid bending speed of 4 meters per minute. The powerful 1500 RPM motor and semi-automatic features make it ideal for businesses aiming to boost productivity while maintaining consistent results.

FAQs of Hydraulic Plate rolling Machine:

Q: How does the hydraulic plate rolling process work with this machine?

A: This machine uses hydraulic pressure to precisely bend and roll mild steel plates. Operators feed the plate into the rollers, where controlled hydraulic force and the 1500 RPM motor shape the steel into the desired bend, achieving consistent bends up to 180 degrees.Q: What types of raw materials can this machine handle?

A: Primarily designed for mild steel plates, the machine offers optimal results within its bending strength and output specifications. For other materials, consult the manufacturer for suitability and adjustments.Q: When is this machine most beneficial in industrial operations?

A: This equipment is essential for industries requiring regular plate bending and rolling at high volume, such as construction, fabrication, and shipbuilding, thanks to its 100-ton monthly output and robust semi-automatic control.Q: Where is the hydraulic plate rolling machine manufactured and supplied from?

A: The machine is engineered, manufactured, and supplied from India, ensuring compliance with international industrial standards while providing localized support and service.Q: What is the typical usage process for operators?

A: Operators set the plate according to the desired bend radius and angle, initiate the semi-automatic controls, and monitor the process as the hydraulic system rolls and bends the material at a speed of 4 meters per minute.Q: What are the primary benefits of using this hydraulic plate rolling machine?

A: Key advantages include high bending strength, rapid output, precise controls, and the ability to customize color. The semi-automatic operation streamlines plate processing, improving productivity and reducing manual effort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PLATE ROLLING MACHINES Category

NC Operated Hydraulic Plate rolling Machine

Price 2700000.0 INR / Number

Minimum Order Quantity : 1 Number

Condition : 1

Place of Origin : India

Automation : Semi Automatic

MECHANICAL PLATE ROLLING MACHINE

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : 1

Place of Origin : India

Automation : Semi Automatic

Hydraulic Plate Bending Machine

Price 4500000 INR / Unit

Minimum Order Quantity : 01 Unit

Condition : 1

Place of Origin : India

Automation : Semi Automatic

|

PRAKRUTI HYDRODYNAMATICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry