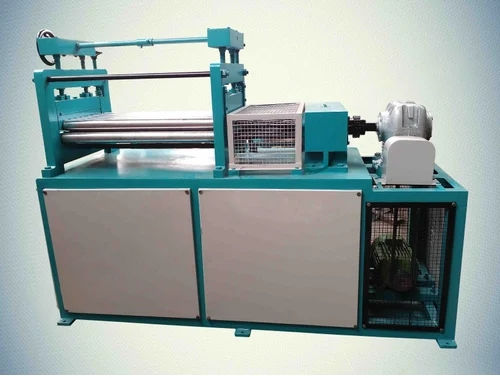

Metal plate Straightening Machine

Price 175000 INR/ Unit

Metal plate Straightening Machine Specification

- Product Type

- Other

- Technology

- CNC

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Surface Treatment

- Painted

- Dimension (L*W*H)

- 3000 x 3000 x 2000 Millimeter (mm)

- Weight (kg)

- 32 Metric Ton

- Color

- AS PER REQUIRED

- Production Capacity

- 200 Tons/year

- Usage & Applications

- Industrial

Metal plate Straightening Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID), Delivery Point (DP)

- Supply Ability

- 5 Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Metal plate Straightening Machine

Industrial Straightening Machine can be used to automatically straighten the rotors for fine tolerances. It is designed and manufactured by using supreme quality raw material with the help of modern machine adhering to set industrial standards and norms. It is highly efficient, robust in construction, optimum in functionality, easy to maintain and it consumes less power. Clients can avail our Industrial Straightening Machine in different technical specifications as per their requirements at reasonable prices.

Precision Engineering for Industrial Demands

This metal plate straightening machine is designed specifically for large-scale, industrial needs. With its CNC-based semi-automatic operation, it ensures even the toughest materials are straightened with remarkable accuracy. Each unit is custom painted to order, providing both practical durability and visual appeal. Indian manufacturing expertise guarantees lasting performance and immediate local support.

High Capacity & Productivity

Able to process up to 200 tons of metal plates per year, this machine is tailored for continuous use in demanding production environments. Its substantial weight offers excellent stability during operation, reducing vibration and improving accuracy. The sizable operational footprint makes it suitable for major industrial workshops.

Advanced Technology & Easy Operation

Utilizing modern CNC technology, the machine streamlines the straightening process while remaining user-friendly. The semi-automatic controls allow operators to achieve precise results with less manual intervention, enhancing both output quality and workplace safety.

FAQs of Metal plate Straightening Machine:

Q: How does the Metal Plate Straightening Machine operate?

A: The machine uses semi-automatic controls combined with CNC technology to straighten metal plates with high precision. Operators load plates onto the machine, set parameters using the CNC interface, and the system automatically aligns the plates according to programmed specifications.Q: What types of industries commonly use this straightening machine?

A: This machine is widely utilized in sectors such as automotive manufacturing, shipbuilding, steel fabrication, and heavy machinery production where precise straightening of metal plates is essential for further processing.Q: When should periodic maintenance be performed on this equipment?

A: Regular maintenance checks should be conducted every six months, or as recommended in the user manual, to ensure optimal performance and longevity. Scheduled inspections cover mechanical components, lubrication, and the CNC system.Q: Where is this machine manufactured and supplied?

A: The Metal Plate Straightening Machine is produced, supplied, and traded by a reputable manufacturer in India, with reliable after-sales support and service available nationwide.Q: What is the straightening process supported by this machine?

A: The process involves feeding metal plates into the machine, which uses CNC-guided rollers and mechanisms to apply precise corrective forces, resulting in flat and uniform plates suitable for further industrial use.Q: What are the main benefits of using this machine in production?

A: Key benefits include enhanced plate quality, improved production efficiency, reduced manual labor, and consistently accurate results. Its sturdy design and large throughput make it ideal for continuous, high-volume operations.Q: How is the surface of the machine treated for durability?

A: Each machine undergoes a specialized painted surface treatment, providing protection against corrosion, wear, and operational hazards, thus extending the service life and maintaining appearance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

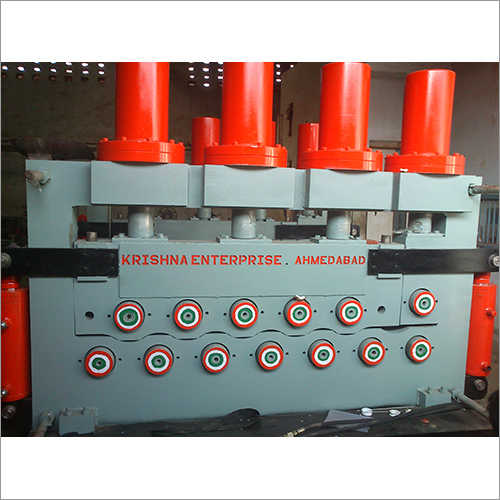

More Products in METAL STRAIGHTENING MACHINE Category

|

PRAKRUTI HYDRODYNAMATICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry